The flame retardancy of fire-resistant materials refers to the ability of materials or products to undergo flame combustion under specified test conditions. It includes some characteristics related to whether it is easy to ignite and whether it can maintain the ability to burn. After years of development, flame retardancy testing has formed multiple standards and become a very important testing item in the relevant industry. We will conduct flame retardant testing on the samples provided by customers, and grade them accordingly based on the combustion results to assist customers in quality control of their products. Flame retardant rating is essential for many certifications and is also a mandatory inspection required by many countries.

Needle flame test is an important testing item in electrical product safety inspection, with a wide coverage However, there are many factors that affect the experimental results during the experiment. Due to the complexity of the experimental operation, on the basis of a correct understanding of the standards, attention should be paid to the operational details and key factors in the experiment in order to effectively ensure the accuracy of the experimental results.

definition:

This experiment is used to determine whether the test flame will not ignite the component or ignite the combustible component under specified conditions, but the duration or length of combustion of the component is limited, and the flame or burning or hot particles falling from the test sample will not spread the combustion.

The main purpose of the experiment is to:

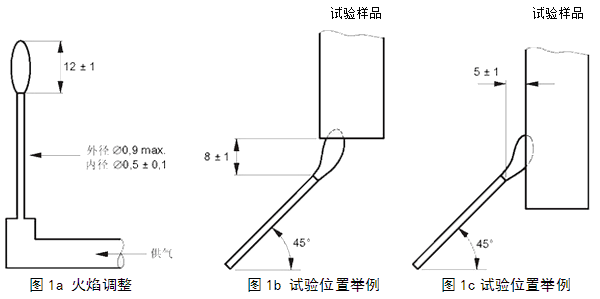

The needle flame tester uses a needle shaped burner with a specified size (Φ 0.9mm), supplied with specific gas (butane), and timed at a 45 ° angle to ignite the test sample. The ignition risk of small flames caused by fault conditions inside the equipment is evaluated based on whether the test sample ignites, the holding time, and the combustion length.

Main experimental methods:

Apply the test flame to the surface area of the test sample that is susceptible to flame influence, which is generated under normal use and fault conditions.

The duration of applying the test flame should be in accordance with the relevant specifications.

The test flame is positioned at the point where the flame tip contacts the surface of the test sample. After reaching the specified time, move the test flame away.

If molten or flame containing material drips from the test sample during flame application, the burner can be tilted 45 degrees from the vertical line. To prevent materials from falling into the combustion tube, maintain a space of 8 mm ± l mm between the center of the burner tip and the remaining part of the test sample, ignoring melted material threads.

When the relevant regulations require conducting more than one point test on the same test sample, attention should be paid to ensuring that the degradation caused by the previous test does not affect the results of the test to be conducted.

Common standards:

GB4706.1-2005 General Safety Requirements for Household and Similar Electrical Appliances

IEC60695-11-5:2016 Needle flame test method Device, Verification Test Protocol, and Guidelines

GB/T5169.5-2008 Fire hazard testing for electrical and electronic products - Part 5: Test flame needle flame test method, apparatus, confirmation test method and guidelines

Sample size:

Finished product samples without special requirements are sufficient.

Schematic diagram of needle flame combustion test